TURN YOUR IDEAS INTO METAL POWDERS

AMAZEMET AT FORMNEXT 2025

AMAZEMET AT FORMNEXT 2025

AMAZEMET will be exhibiting at Formnext 2025 in Frankfurt, Germany, taking place from November 18-21. Find us at Hall 12.0, Booth E59. Our partner, ACONITY3D, will also be at our booth to showcase their products alongside our technology.

This year’s advancements at FORMNEXT 2025

This year at Formnext, we are demonstrating three key developments designed to enhance the efficiency, flexibility, and operational accuracy of alloy development and powder production. We are introducing the AI-Driven Process Automation system, an integrated upgrade that enables autonomous operation of the rePOWDER platform, alongside the expanded material capability provided by our new Laser Melting Source. Finally, we are formally launching our Atomization Services, providing researchers and engineers direct, cost-effective access to custom, small-batch metal powders produced with ultrasonic atomization technology.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

IN ALLOY DEVELOPMENT

Ai-Driven Atomization

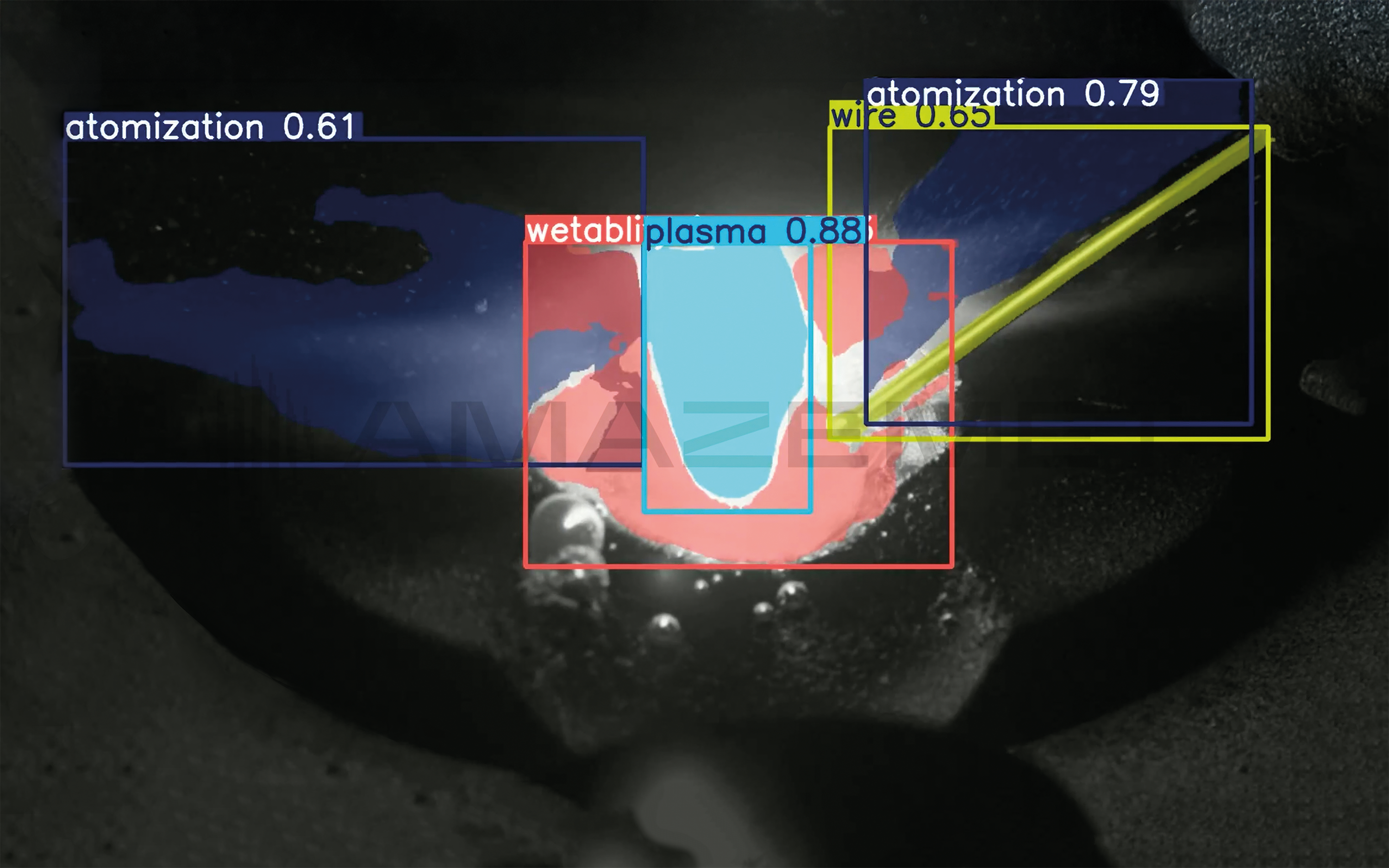

This year, AMAZEMET is introducing a significant advancement to our rePOWDER platform: a new, integrated system for AI-Driven Process Automation. This upgrade integrates a proprietary Ai-Vision model to enable fully autonomous process management for alloy development and powder production.

Using real-time visual analysis, the system monitors the material on the sonotrode, feeding rate, and the atomization process itself. This development allows for experienced operator-level efficiency and continuous operation for extended periods, enabling a single operator to supervise multiple machines.

Remote Operation and API Integrations

Dedicated API enables integration with industrial networks (MES/ERP), remote process control, comprehensive supervision (including camera feed access), and centralized data logging.

Edge Ai Computing

Contains a dedicated, industrial-grade GPU to execute the Ai model in real-time, ensuring minimal latency (approx. 120 ms) and rapid process adjustments.

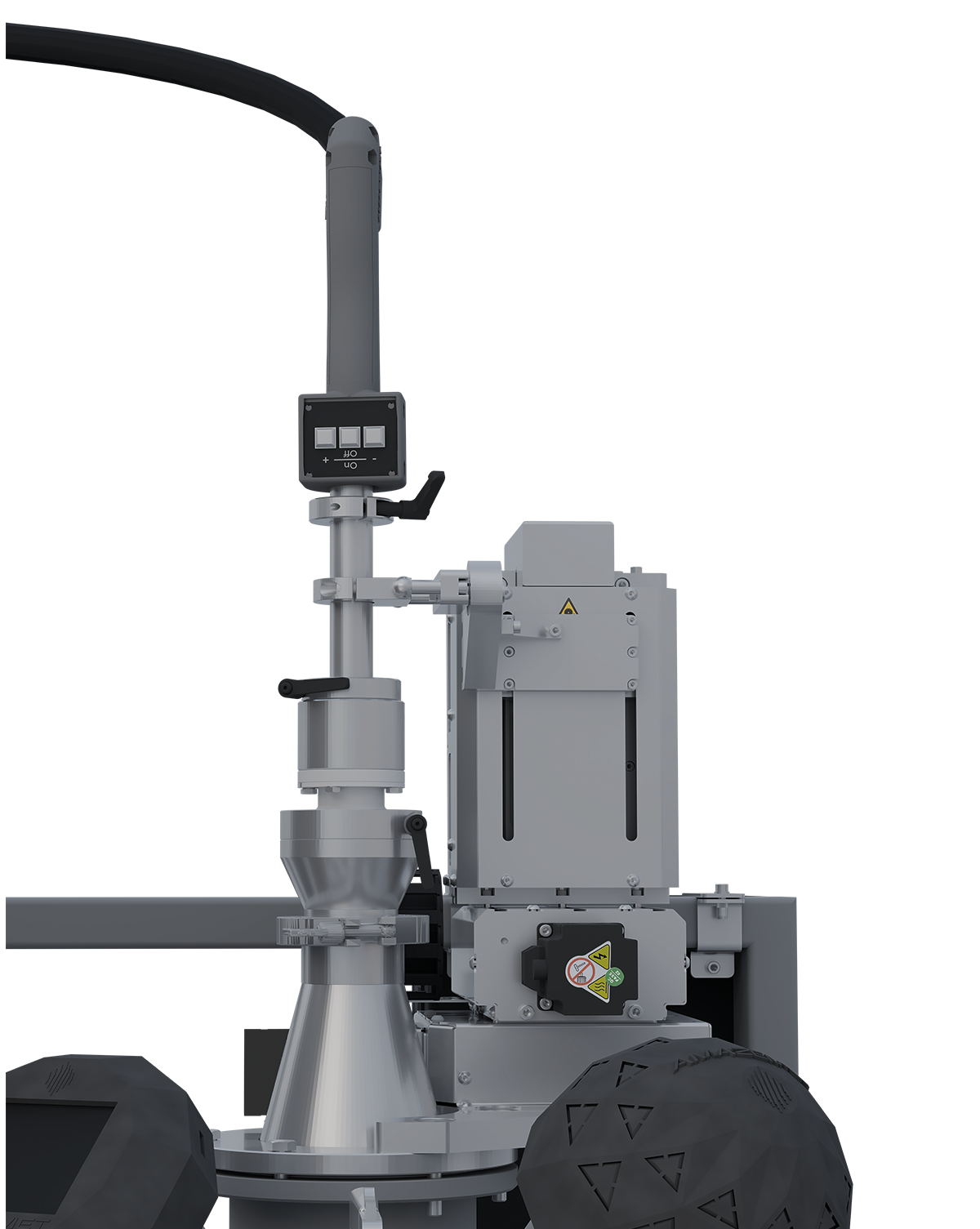

New Custom Plasma Source

Plasma Source Integrates a new, custom plasma source, optimized for the rePOWDER platform and engineered for high reliability and overload resistance.

Integrated Recirculation System

This new design integrates the recirculation system directly into the cabinet structure, reducing the total platform width by 68 cm, and making its footprint even more lab-friendly.

Passivation & Filter Cleaning

Improved filter cleaning procedure which now includes a passivation cycle, extending component life and maintaining system purity.

Ai-Vision Control

Executes continuous, real-time positional adjustments based on the real-time Ai’s visual analysis of the melt pool via industrial-grade camera.

Process Parameter Control

Autonomously modulates plasma current, ultrasonic power, and gas flow. The system will, for example, pause wire feeding if it detects poor material wettability or overfeed of atomized material.

Intelligent Sequences

Executes complex, automated sequences, including sonotrode scanning, oxygen level verification, and arc start/stop protocols.

Manual Override & Alarms

The operator can also manually intervene or pause the autonomous process at any time. Process alarms will automatically interrupt any sequence.

Automated Self-Cleaning

Initiates a self-cleaning procedure using a dedicated gas blower to clear process buildup from the sonotrode, minimizing downtime.

Precision Delivery

Ensures high-accuracy, stable feedstock delivery, which is critical for maintaining melt pool consistency.

Consumption Monitoring

Provides precise tracking of material usage for process documentation.

Dynamic Feed Rate

The material feed speed is automatically adjusted in real-time to match process demands.

High Stability Feedstock Delivery

Ensures accuracy and stability in feedstock delivery.

LASER MELTING SOURCE

AMAZEMET has announced the development of a new high-energy laser source. This latest innovation, developed under the EU-funded project aims at enabling next-level efficiency and purity for ultrasonic atomization process.

Compared to conventional TIG or plasma-based melting systems, the laser-based energy source provides a highly concentrated and cleaner heat source that ensures more efficient atomization of high-performance materials. The new melting source will seamlessly integrate into the rePOWDER atomization platform, further strengthening AMAZEMET’s position at the forefront of metal powder processing technologies.

1

EXPANDED MATERIAL RANGE

The high-intensity laser enables the atomization of a broad range of materials, from lightweight aluminum to high-melting-point metals like titanium and niobium.

2

CLEANER AND MOrE PRECISE MELTING

The process eliminates the need for consumable electrodes found in TIG and plasma torches, avoiding tungsten contamination and minimizing undesired element evaporation.

3

IMPROVED POWDER QUALITY

By eliminating contamination risks associated with traditional plasma sources, we achieve cleaner, more controlled atomization with improved powder quality.

4

INCREASED PROCESS EFFICIENCY

The laser ensures precise energy input on the sonotrode surface, enabling advanced scanning strategies that optimize material melting, enabling the users to from employ expertise from Laser Powder Bed Fusion (L-PBF) and Electron Beam Powder Bed Fusion (EB-PBF).

C103

NbWReRu

ATOMIZATION SERVICES

ON-DEMAND

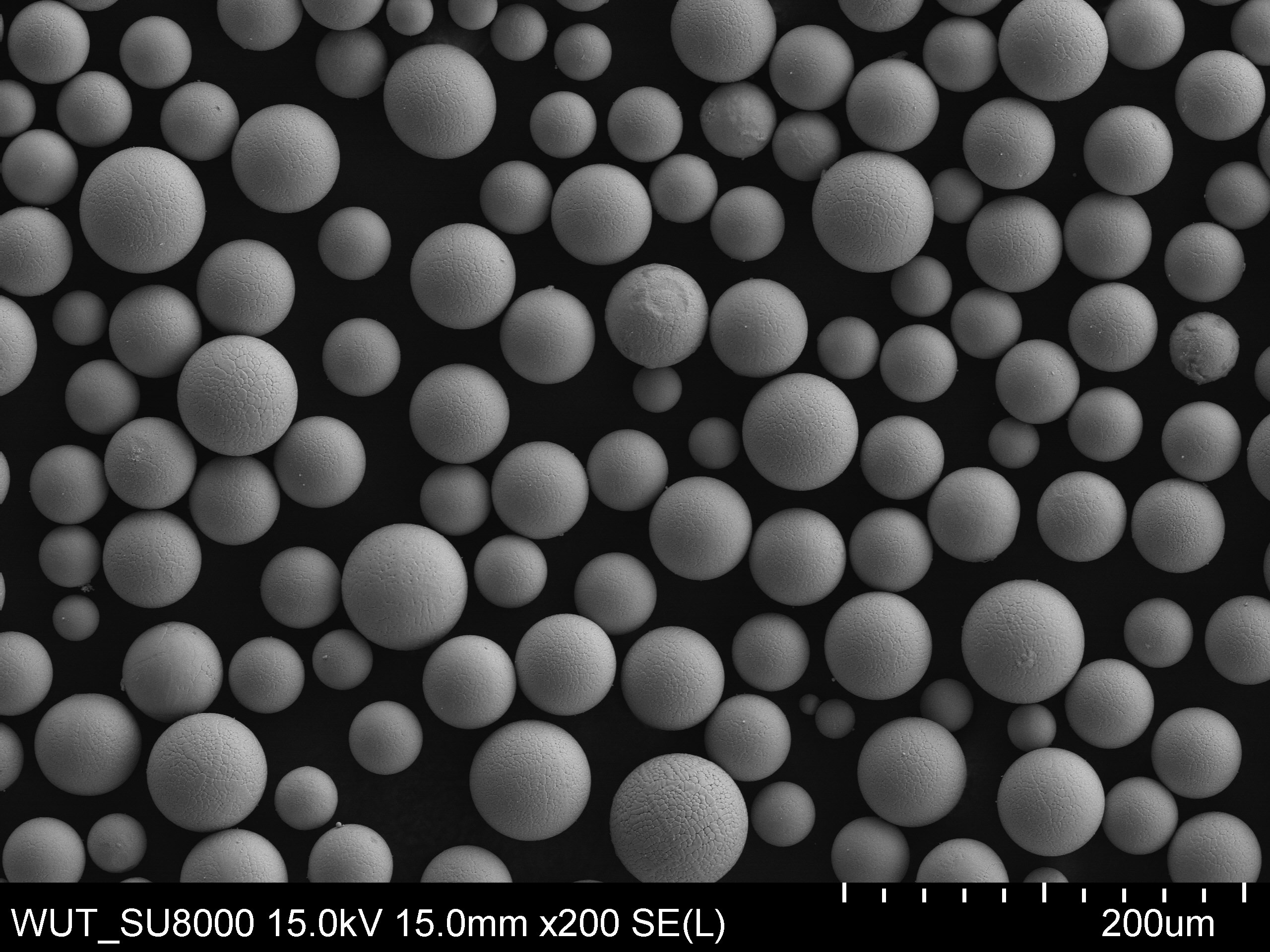

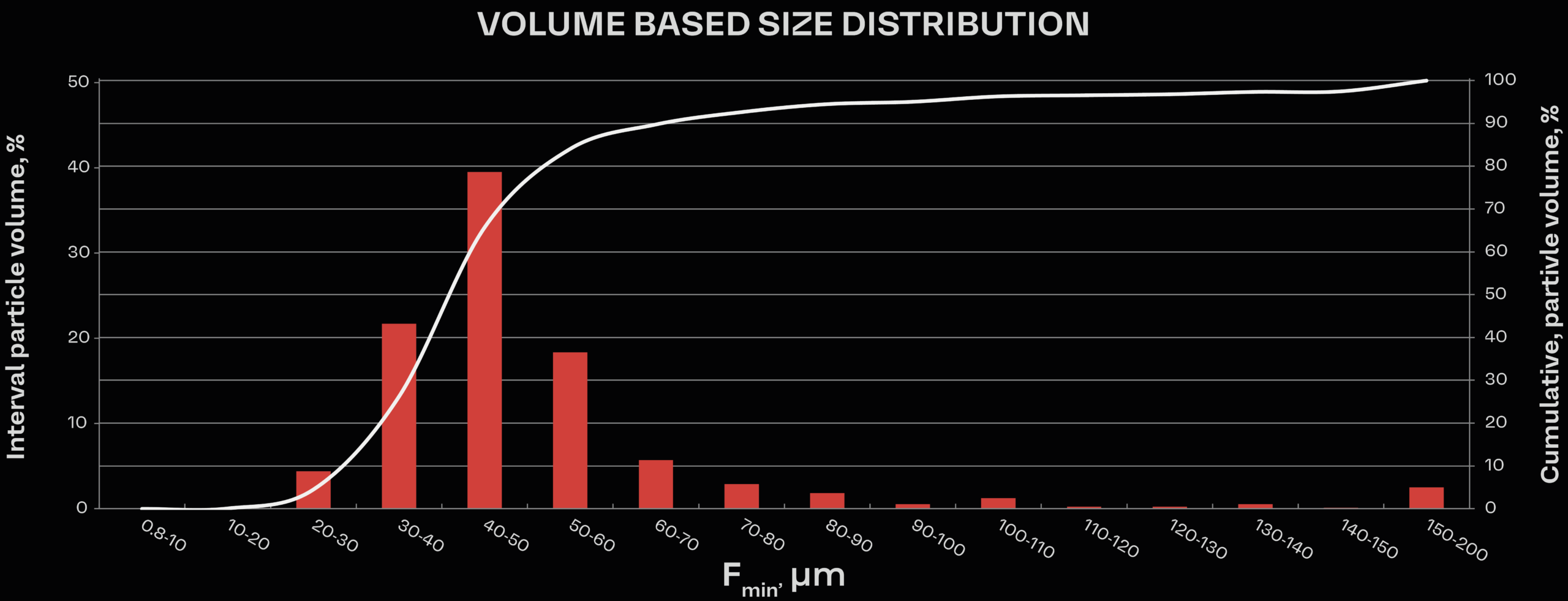

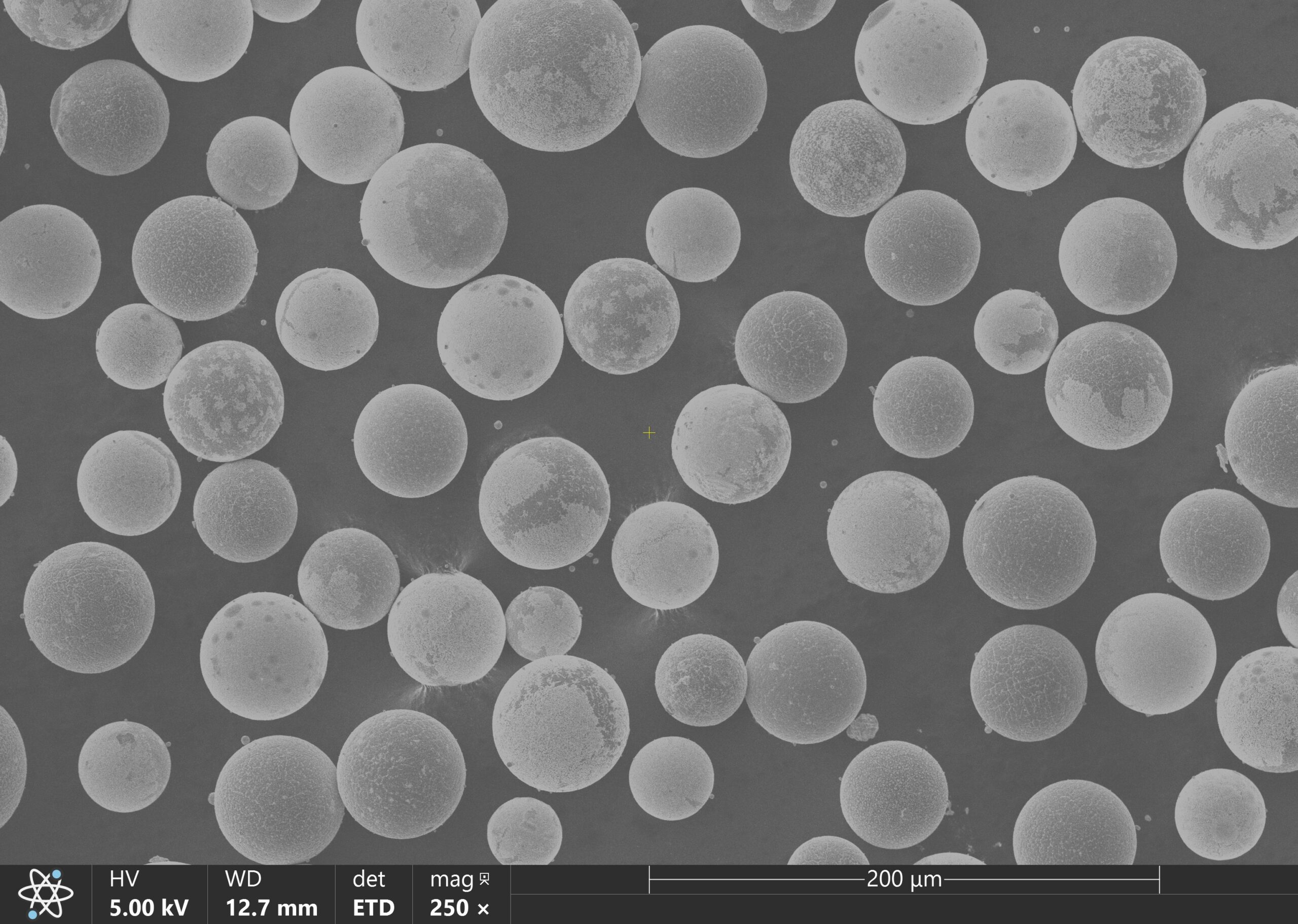

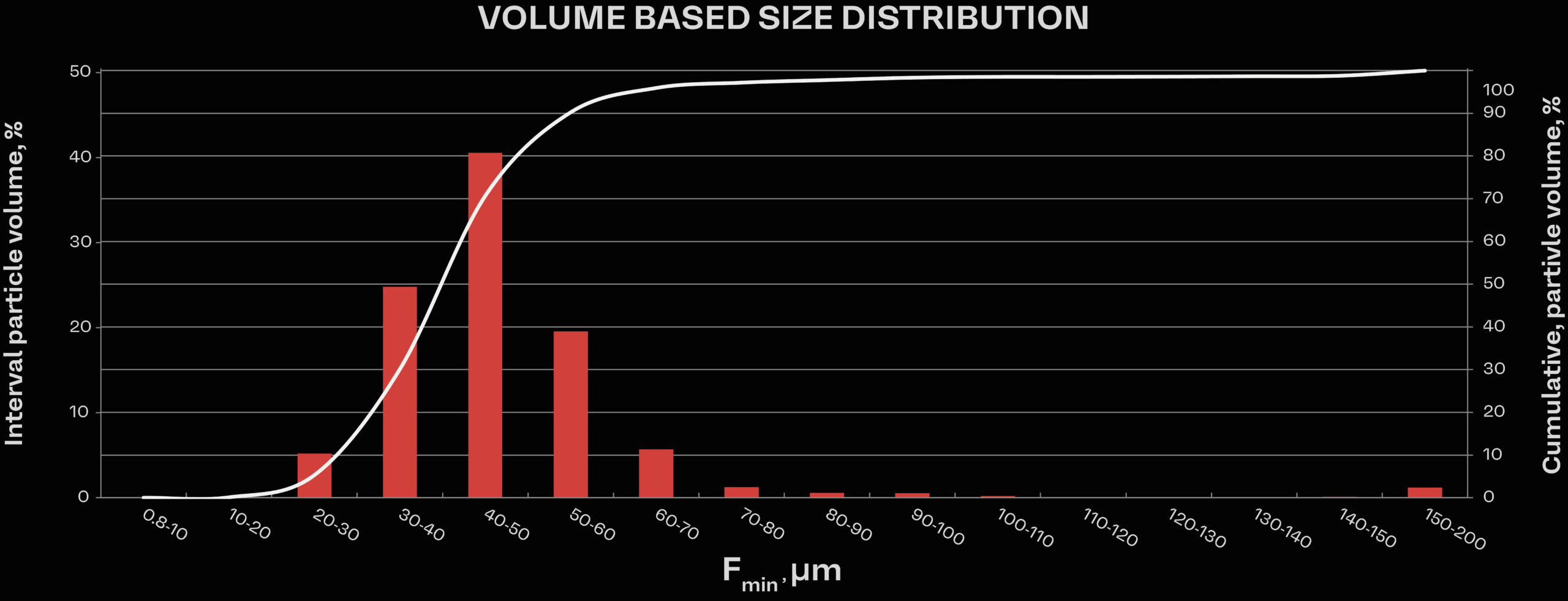

At AMAZEMET, we produce high-quality metal powders using advanced ultrasonic atomization technology. It allows us to create cutom powders with superior characteristics, ensuring optimal performance in your applications. Our process offers:

- Narrow Particle Size Distribution:

Ensuring precision and uniformity. - Near-Perfect Sphericity: Enhancing flowability and packing density.

- Satellite-Free Powders: Delivering clean surfaces without unwanted particles.

- Unoxidized Surfaces: Achieved through high purity process atmosphere.

- Low Inert Gas Consumption: minimizing costs of atomization.

Atomization Service by AMAZEMET includes:

- Low Barrier to Entry

- High Process Efficiency

- Customized Material Capability

- Unique Recycling Options

- Pre-Alloying Service

- Multi-Material Orders

AMAZEMET commits to full transparency by sharing all relevant processing parameters with the client. The company’s application team, consisting of materials science experts (PhDs and PhD candidates), will also provide support in preparing research papers.

SCHEDULE A MEEETING AT FORMNEXT 2025

To schedule a dedicated meeting with our Application Engineers at Booth E59, Hall 12.0, please use the links below: